welding sheet metal parts Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more Metal boxes must be grounded whether exposed or not (and regardless of the type of covers). You can use plastic covers on metal boxes. Metal covers require that you use a proper method to ground them as well. Typically being screwed to a grounded metal box or a grounded device (receptacle/switch) suffices.

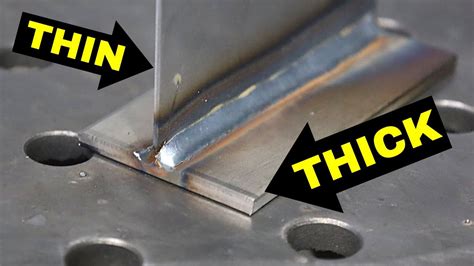

0 · welding thin to thick metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · welded sheet metal manufacturing

4 · sheet metal welding methods

5 · best welding for thin metal

6 · best welder for sheet metal

7 · 18 gauge weldable sheet metal

$9.99

welding thin to thick metal

Each welding process requires specific precautions and equipment setup for a successful sheet metal weld. So, let’s discuss the preparation needed for each arc welding process before proceeding to the common problems with thin gauge welds. See moreNow that we’ve covered the essential considerations for different arc welding processes, let’s discuss how to prevent and fix common . See more

Welding thin metal is challenging. There is no denying that. But, if you practice and use the tips we shared in this article, you’ll get the best chance for success. After you inevitably burn through some scrap sheets of metal and warp others, you’ll gain more experience and learn . See more

what is black iron sheet metal

A Guide to Different Methods of Welding Sheet Metal Fabricated Parts (Updated for 2024) Precision Sheet Metal Fabrication , Sheet Metal . Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these . There are different sheet metal welding techniques, but do you know which is best for your industrial applications? This article provides a detailed view of the various methods used in welding sheet metal, including their . Sometimes even professional welders may have trouble welding thinner materials. This is due to many factors that came into play. In this article, I am going to explain the .

Today we will be going over some tricks to weld thin gauge sheet metal like body panels while avoiding wrapage. I go over 2 different techniques and several .Let’s cut to the chase: welding sheet metal involves a meticulous process that fuses two pieces of metal by using heat to melt the parts and then allowing them to cool, causing fusion. The goal is to create a robust and seamless bond that .

Spot welding involves fusing two or more layers of sheet metal by passing an electrical current through metal pins, creating a coin-like deposit at the point of contact. Seam welding, on the other hand, creates a smooth, . The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW. Gas Tungsten Arc Welding (GTAW or TIG) GMAW (MIG-MAG Welding) FCAW. Spot Welding. Seam welding. .

Welding can cause some distortion and sheet metal is particularly sensitive. Learn how to reduce warping with these tips. Welding autobody panels. Auto body sheet metal is relatively thin, and this can present some challenges .Such as cabinet welding, robot welding can be used, which can save a lot of tasks and improve work efficiency and welding quality. CO2 gas shielded welding is used for iron plate welding; argon arc welding is used for aluminum plate .Acrux7 16 PCS Butt Welding Clamps, Small Sheet Metal Clamp, Carbon Steel Panel Clamps for Auto Body Edge to Edge Welding (1x2.3 Inch) 4.6 out of 5 stars. 11. 50+ bought in past month. .69 $ 17. 69 (.11 .11 /Count) FREE delivery Sat, . Understanding Brazing And Welding Sheet Metal. Brazing and welding sheet metal may seem similar but have significant differences. Brazing is the process of joining metal parts using a filler that melts and solidifies to form .

Its versatility, durability, and aesthetic appeal make it an excellent choice for many applications. At Shengen, we provide high-quality, customized sheet metal parts for different industry needs. Importance of Welding in Sheet Metal Fabrication. Welding is a crucial process in sheet metal fabrication. It allows us to combine two pieces of . Welding autobody panels. Auto body sheet metal is relatively thin, and this can present some challenges for welders particularly those who are accustomed to welding thicker materials. . panels may distort less if the weld is made in smaller segments — welding 1 inch at a time and skipping to different parts of the joint to keep the heat down.

Welding is a process that joins metal parts together. It is one of the most common methods for making connections between metal objects, and there are many different types of welding. is Sheet metal welding a subset of welding used to construct metal structures, piping, and other things such as storage tanks?

Last updated on May 2nd, 2024 at 11:58 am. Not all metal fabrication shops have extensive expertise in welding and riveting.But at Approved Sheet Metal, we know both techniques like the backs of our hands and have plenty of experience helping customers choose between these two excellent methods for joining custom sheet metal parts.

In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and we.Methods for Sheet Metal Welding. Let’s delve into an in-depth exploration of various methods employed for sheet metal welding: MIG Welding. Metal Inert Gas welding (MIG), or Gas Metal Arc Welding, utilizes a continuous solid wire electrode fed into the weld puddle with a welding gun.Sameer Exports specialized in Auto Parts & CNC Turning Components , Sheet Metal ( Stamping Parts ) & Deep Drawn Components ,Gate Fittings & Supports , Pipe Manipulation & Bending welding , Casting & Wire Products , Fence Fittings making us the trusted choice for our customers need. In-House Tooling & Engineering.Fusing Sheet Metal Parts Welding vs Riveting. Stay Connected! Stay tuned for more updates! Get Updates. I agree to receive email messages containing service updates and Design Tips from Protolabs and its affiliates. Proto Labs, Inc. 5540 Pioneer Creek Dr. Maple Plain, MN 55359 United States . 877-479-3680 [email protected] Services. Injection .

Shielded Metal Arc Welding (SMAW) SMAW or stick welding is a welding technique that involves using a flux-coated electrode connected to a power source to weld the sheet metal parts. The molten electrode fills the space between the .KDM uses different welding techniques such as spot welding, TIG welding, etc. Aside from that, KDM is also an expert in sheet metal assembly, burning, hole punching, . Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you . Sheet metal welding is a process that seems relatively simple at first glance – connecting several metal parts with the help of high temperatures and filler material. However, there is a lot more to it than just this explanation, which is why this article would try to explain basic welding methods and offer several tips for sheet metal welding.

Welding: Sheet metal parts are joined together using welding processes, such as MIG welding, TIG welding, and spot welding. Sheet metal finishes. Sheet metal parts can be finished in a variety of ways to improve their appearance and performance, including: The spot welding process is one of the oldest welding methods used. Its primary usage is in welding auto body and sheet metal. Spot welding is usually used to join a panel of overlapping sheet metal, parts that are usually .

Fusing Sheet Metal Parts Welding vs Riveting; Tech Tips. March 12, 2020. Welding vs. Riveting: Fusing Sheet Metal Parts. By Steve Konick. If you’re designing a part that requires you to fuse two pieces of sheet metal . Welding sheet metal is a very critical process within the modern concept of manufacturing. The construction of metal structures, pipelines, and tanks is among the most common applications for sheet metal welding. . In this way, the required metal constructions, parts, and assemblies can be made effectively by manufacture. The temperature in .

Our sheet metal welding expertise extends to various industries and applications, including automotive, aerospace, construction, electronics, and more. . Resistance welding is a welding process in which metal parts in contact are permanently joined by heating them with an electric current, melting the metal at the joint. Electric resistance . For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm).

Established in 1997 as a stamping welding manufacturer in Laizhou Shandong China, Laizhou Kailai Machinery Co., LTD has evolved over the years into a first-class, build-to-print contract manufacturer of sheet metal parts.

Sheet metal fabrication for chassis, tanks, enclosures, and other sheet metal parts. Last updated on February 23rd, 2024 at 08:51 am. . Some local shops may push back on the customer to change the design or jump to cutting the parts in multiple parts and then welding it back together. At ASM we have the talent and know-how to use an old . Manufacturers often have to fit several parts to make a whole during fabrication. Sheet metal welding is a crucial manufacturing process that helps join and assemble metal structures. However, it’s a relatively complex process that requires technical skill to ensure your fabrication meets industrial standards. This article introduces you to welding sheet metal, . I'm Presently rebuilding an 65 sa 200 red face (read orange now) I just went to a sheet metal shop and had them roll a new canopy out of #4 -18 guage s.s. reasonable enough by canada's standards 370.00 cdn dollars. Ensure you use very thin wires when working with reedy, thin sheet metal. Metal Thickness (inches) Recommended MIG Wire Size (inches) 0.024: 0.020: 0.030: 0.023: 0.036: 0.025: 0.048: 0.030: 0.060: . Welding thin metal is sometimes harder than welding massive chunks because the likelihood of burning through and damaging the base metal is much .

what is nibbling in sheet metal

Get a free quote Specialist in Custom Metal Parts OEM Production When it comes to customized metal parts manufacturing, Sinoway is absolutely the right-matched option. . Welding; Surface Finishing; INDUSTRIES. Industrial Machinery; Electrical Appliances; . And sheet metal parts constitute the machinery bodies. Find Products. VIEW ALL .

Riveting is a lower method of joining sheet metal parts than welding. It takes more time because it necessitates drilling the hole, hammering the tail, and heating. Welding is a quick process. You can achieve a speed of 40 to 140″ / minute with laser beam welding. Material types : Riveting is applicable for all types of sheet metal parts.

$18.88

welding sheet metal parts|sheet metal welding methods